Understanding Steel Platforms: Space Optimization in Material Handling, Warehousing and Distribution

Steel platforms offer a practical way to turn unused vertical space into valuable working or storage areas.

In material handling, warehousing and distribution environments, steel platforms (also called steel mezzanines) improve efficiency by expanding capacity without the cost or disruption of new construction.

These structures can be customized and provide the flexibility to meet a wide range of operational needs.

Short on time? Download the contents of this page in our Understanding Steel Platforms Guide, including a bonus section of product specifications!

Steel Platforms and Mezzanines: A Practical Solution for Vertical Space Utilization

A steel platform, also called a steel mezzanine, is an elevated structure made from a framework of steel columns, beams, and decking that creates a new level within an existing facility.

Designed to support people, equipment, and product flow, steel platforms are engineered for strength, durability, and to optimize vertical space.

By adding a steel mezzanine or platform, facilities can put unused vertical space to work. Platforms can expand usable floor area and often double or triple capacity without the cost and disruption of new construction. Steel platforms can be integrated in a variety of operations, including:

- Warehouses

- Manufacturing plants

- Distribution centers

- Retail environments

Steel Platform Advantages

Steel platforms provide measurable economic and operational benefits. When facilities run out of floor space, the choice often comes down to costly construction or getting more out of what you already have. Steel platforms make that decision easy. By transforming unused vertical space into productive square footage, platforms provide a smart, flexible, and cost-effective way to scale operations without the disruption of major building projects.

- They allow expansion within the current footprint, avoiding land acquisition and building costs.

- At about one-fifth the expense of new construction, steel platforms add new, usable space for storage, production, or offices.

- They can be disassembled and relocated as needs change, and can be customized to support heavy equipment, integrate with conveyors or create multi-level work environments.

- By using vertical space, mezzanines improve inventory control, streamline workflows and can qualify for accelerated tax depreciation.

Platforms and mezzanines offer functional support for some of the most demanding environments in material handling, manufacturing, and commercial spaces. Whether your project calls for robust equipment support, efficient space expansion, or enhanced employee amenities, steel platforms can be tailored to meet precise operational requirements, integrate seamlessly with existing systems, and deliver long-lasting performance.

Steel platforms can offer improved flow, function, and space utilization, including:

- Storage for parts, materials, and inventory

- Equipment support platforms

- In-plant offices and administrative space

- Work platforms for assembly or inspection

- Catwalks and crossovers for safe access across production lines

- Locker rooms, cafeterias, and employee areas

- Retail display and trade show structures

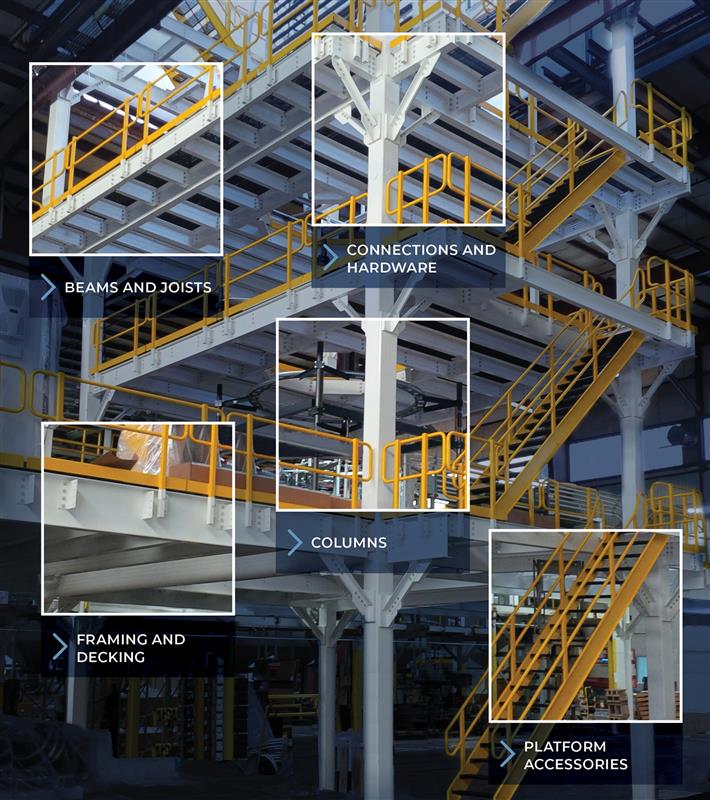

The Anatomy of A Steel Platform

Every platform consists of interconnected components, each engineered for strength, safety, and functionality. Together, these elements create a stable, load-bearing system that can be adapted to a wide range of industrial, commercial, and material handling applications.

Columns

Columns are the vertical supports that transfer the weight of the platform, its contents, and any live loads down to the facility floor. Columns are precisely spaced and sized to handle the required load capacity while allowing for maximum usable space below the platform.

Beams and Joists

Beams and joists are the horizontal framing members that connect columns and form the main structural skeleton. Primary beams span between columns, while joists or secondary framing members run between beams to support the decking.

Connections and Hardware

High-strength bolts, welds, and fastening systems secure each component, ensuring structural integrity and stability under dynamic loads. These connections are engineered to meet or exceed building code requirements and industry standards.

Steele Solution’s Moment Connection is a connection joint between a beam and a column where the end of the beam is restrained from rotating, creating a rigid frame without the use of conventional cross-bracing. Our Moment Connection is the fundamental building block of our platforms. It provides a number of benefits such as increased usable space, safer walkways, and faster installation. Even in high seismic areas, our moment connection does not require knee bracing of any kind.

Framing and Decking

Structural framing and decking are the surface of the platform where people, equipment, and materials are placed. Framing and decking are engineered to match the span, load requirements, and operational layout of each project. Options include cold-formed C-channel construction for shorter spans and bar joist construction for wider spans where fewer columns are desired.

Deck surfaces are selected based on use, load, and environmental conditions. Common configurations include:

- Steel roof deck with high-density wood for an economical, durable surface that supports pallet jack loads up to 4,500 pounds and is comfortable for foot traffic.

- Steel roof deck with concrete for heavy-duty manufacturing or wet washdown areas, offering both fire and sound resistance.

- Steel floor plate for environments requiring maximum durability and fire resistance, such as food processing or foundries.

- Bar grating for applications where light, air or sprinkler penetration is essential.

Other options, such as fiberglass, aluminum plate or custom composites, can be specified for specialized environments.

Check out our blog to learn about the three essential elements of platform design.

Platform Accessories

Accessories add safety, access, and efficiency to a mezzanine installation. Steele Solutions offers:

- SteeleTrax, a proprietary system for conveyor and equipment integration

- Catwalks, crossovers and access structures for improved movement across operations

- Stairs, landings, gates and ladders engineered to meet applicable codes

- Handrails, guardrails and kick plates to protect personnel and meet safety requirements

A well-designed steel platform is more than an elevated floor. It is a tailored solution that addresses operational needs, maximizes space and supports growth.

How Steel Work and Equipment Platforms Optimize Commercial and Industrial Spaces

Structural steel work and equipment platforms provide one of the most cost-effective ways to expand within an existing facility. By building upward instead of outward, businesses can use underutilized vertical space to create new work areas, storage zones, or equipment platforms, while keeping operations in place.

- Economically Increase Your Usable Floor Space

A steel platform can be built for a fraction of the cost of a building addition. This approach eliminates land acquisition costs and minimizes disruption, allowing production or warehousing to continue during installation. - Increase Storage and Storage Options

Platforms create accessible storage above the floor, freeing prime ground-level space for larger or heavier items. Lighter parts, small materials, or infrequently used inventory can be kept above, while the lower level supports high-traffic operations. - Support Your Equipment

Equipment such as air handling units, conveyors, feed hoppers, and automated systems can be relocated to a mezzanine, opening floor space for core activities. Platforms can be designed for heavy loads, ensuring reliable support and easy access for maintenance. - Create More Office Space

Steel platforms offer a simple way to add offices without reducing production or storage capacity. Administrative areas, quality control offices, and supervision stations can be placed on a platform, keeping them close to operations while preserving floor space for revenue-generating activities. - Create Better Access to Your Plant and Process

Platforms can connect work areas, provide safe passage over production lines or serve as elevated workstations. Catwalks and crossovers improve movement through the facility and enable direct access to machinery, conveyors, or elevated processes. - Efficiently Integrate Your Process

By moving indirect operations or equipment to mezzanine space, floor layouts can be reconfigured for better workflow. This added flexibility supports process improvements, reduces interference between tasks and helps teams work more efficiently. - Less Hassle Than New Construction

Because work platforms and mezzanines are pre-engineered and manufactured off-site, installation is faster and less disruptive than a traditional build. The structure arrives ready for assembly, meets all applicable codes and can be installed around ongoing operations.

How do different design elements and materials influence the cost? Learn more in our blog, “The Cost of a Mezzanine.”

Steel Platform Selection and Design Steps

Selecting a platform or mezzanine begins with knowing exactly what the operation needs and understanding the conditions of the site. The following nine steps provide a framework for creating a platform that delivers long-term structural integrity, safety, and reliable performance:

Step 1: Establish the Application Requirements

Step 1: Establish the Application Requirements

Clarify the mezzanine’s purpose, including what it will store or support, expected traffic, and required features. Plan for future expansion or relocation to keep the design adaptable.

Step 2: Evaluate the Structural and Floor Layout Characteristics

Evaluate space, ceiling height and floor slab capacity. Consider column placement, span and load needs, and confirm slab strength with a slab analysis and soil bearing capacity for safe installation.

Step 3: Governing Body Compliance

Ensure the platform meets building codes, OSHA rules, and local regulations. In seismic areas, add engineering for safety, and have a Professional Engineer certify compliance.

Step 4: Evaluate the Most Common Construction Types/Methods

Structural steel platforms may be built on-site, custom-made, or modular. Custom designs offer the most flexibility, fitting around existing equipment and meeting precise load and space needs.

Step 5: Select a Design Style

Select freestanding for maximum flexibility or shelving/rack-supported for combined storage and workspace. Catwalks and full-mat layouts add access and large upper-level areas.

Step 6: Select the Deck Surface

Decking impacts durability, safety, and performance. Choices include high-density wood for versatility, concrete for heavy-duty or wet areas and steel plate or bar grating for high loads or airflow needs.

Step 7: Select the Paint Color and Finish

Finishes protect the structure and extend its life. Powder coating offers durability and color options, wet spray suits heat-sensitive parts and galvanizing resists corrosion in harsh or wet environments.

Step 8: Structural Options and Accessories

Add safety and function with engineered stairs, handrails, gates, and kick plates. Integrate SteeleTrax framing members, conveyors, lifts or other systems to boost efficiency and workflow.

Step 9: Choose a Steel Work Platform Manufacturer

Choose a provider with proven experience and engineering skill. Ensure they handle design through installation, meet codes, and offer warranties for performance.

Platform Safety Considerations

Protecting people on and around platforms begins with addressing fall risks, which remain the most common cause of workplace injuries.

Guard systems must be designed to match both code requirements and how the platform will be used. Steele Solutions offers two-rail and three-rail configurations that meet IBC and OSHA standards, as well as enhanced designs for locations with higher occupant loads or more demanding safety needs.

Access plays a significant role in overall safety. Stairs provide the most secure route but require more space and a higher investment, while ship’s ladders and vertical ladders conserve space yet introduce greater risk. At entry points, spring-loaded gates help reduce hazards by ensuring an enclosed barrier when the opening is not in use.

For moving materials, options such as sliding or swinging gates can be effective, though many facilities now choose pallet safety or pivot gates to eliminate exposed edges during loading.

Safe design also extends to how the platform is laid out. Adequate walking space, logical placement of access points, and clear visual cues all contribute to a safer, more efficient environment for anyone working at height.

How you use a platform also contributes to overall safety. Learn more by reviewing the different types of platform load.

The best partners manage the entire process, from initial site evaluation and design through fabrication, installation and code compliance. This approach streamlines communication and reduces the risk of delays or costly rework.

By choosing a company that combines engineering skill, industry experience, and full-service capabilities, you set the foundation for a safe, efficient, and lasting platform solution.

Platform FAQs

A steel platform’s capacity depends on its design, materials and intended use. Platforms can be engineered for light-duty storage, heavy manufacturing equipment or anything in between. Load ratings are determined during the design process to ensure the structure safely supports the planned application. Learn more about platform loads here.

Yes, many platforms and mezzanines are specifically designed for disassembly and relocation. This makes platforms a flexible long-term investment. If relocation is a possibility, this should be discussed early so the design can accommodate future moves.

In most locations, yes. Mezzanines must comply with local building codes and OSHA requirements, and drawings often need to be stamped by a Professional Engineer. Your manufacturer should guide you through the permitting process.

Installation timelines vary based on size, complexity, and site conditions. Pre-engineered and pre-manufactured steel platforms can often be installed in a matter of days with minimal disruption to operations.

Routine inspections are recommended to check for loose fasteners, worn decking, or damaged safety components. Keeping the platform clean and promptly addressing any issues helps maintain safety and prolongs the life of the structure.

Maximize your facility’s potential with a platform designed for your specific needs. Download our complete Understanding Steel Platforms Guide to save and share!

Ready to start your project? Contact Steele Solutions to speak with an experienced team member about your platform requirements.

For more insights, visit these related resources: