Supply Chain Ecosystem Changes: 3 Key Takeaways from MODEX Show (2024)

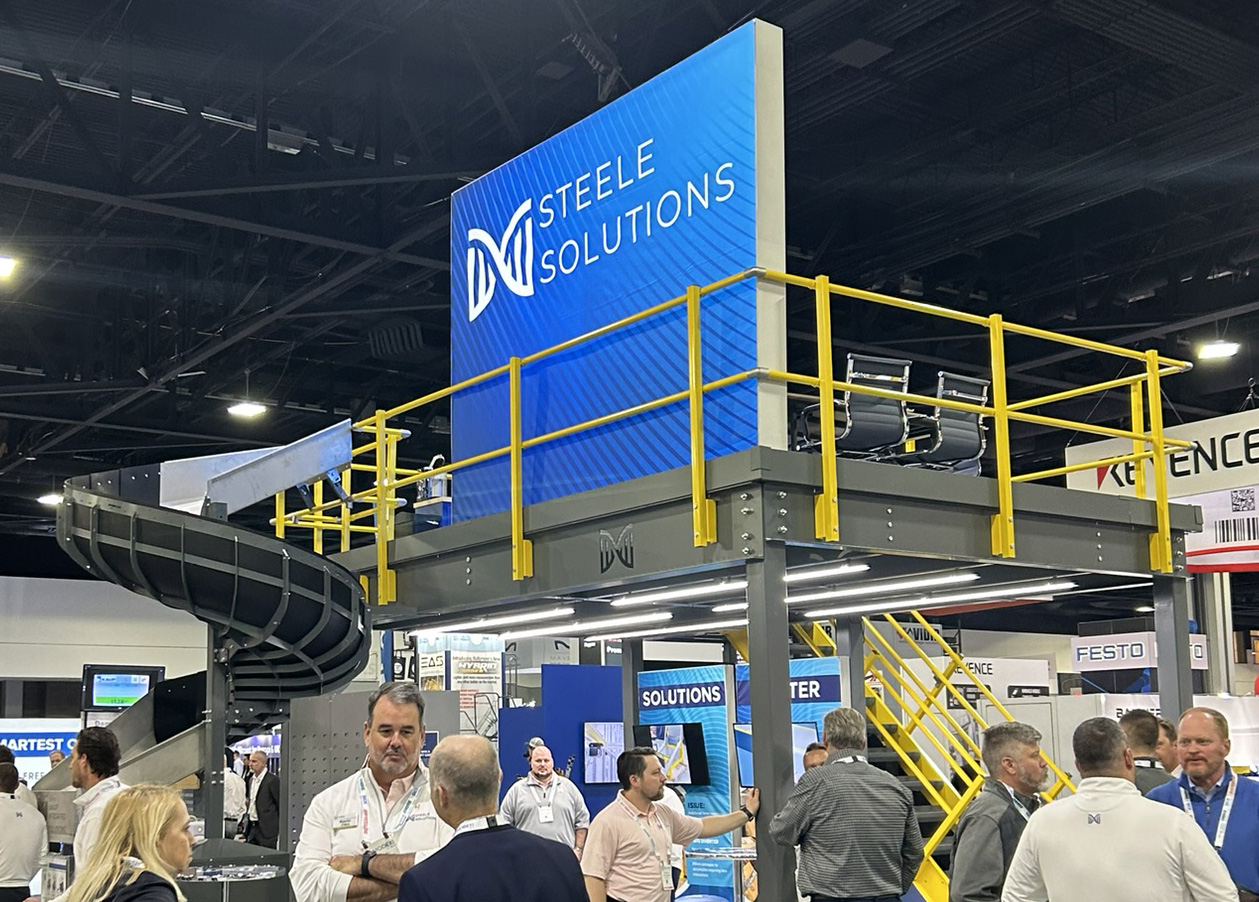

With another successful booth at the MODEX Show now in our rearview mirror, we’re grateful to have had the opportunity to meet with end users, integrators, and general contractors.

In case you missed the conference or didn’t have a chance to catch all of the exciting industry developments, we’d like to share three big takeaways from this year’s show.

Key Takeaways from MODEX 2024

At this year’s event, we observed a clear focus on enhancing efficiency and reliability across the supply chain, with particular emphasis on parcel automation, the critical nature of project execution, and the value of forming versatile, long-term partnerships. We explore each of these insights in more detail below.

#1 Push for More Parcel Automation

Parcel delivery automation is emerging as a significant industry trend. In 2024, industry leaders are accelerating the integration of automated processes to address a critical labor shortage, stimulate further growth, and respond to an overall market resurgence.

This shift is crucial for large-scale operations, delivery services, and the entire supply chain ecosystem.

- Recent internal research from Amazon has highlighted a startling forecast: the potential for a hiring deficit in U.S. warehouses within the next year.

- The labor shortage is underscored by a report from the U.S. Bureau of Labor Statistics, which noted a record number of job vacancies and resignations in the transportation and warehousing sector.

Businesses that leverage automation can expect improvements in speed, accuracy, and consistency in parcel handling, which are essential for customer satisfaction and retention.

Investing in automation technologies is not just a response to current challenges — it’s a strategic move to ensure resilience and efficiency in an increasingly competitive landscape.

The pace at which automation is being adopted in the parcel industry is not just a trend; it’s a fundamental shift in how we approach logistics,” says Andy Schumacher, Chief Revenue Officer, Steele Solutions. “We see this as a direct response to the labor challenges that are becoming increasingly apparent.”

#2 Project Execution is Critical

With significant industry evolution occurring on multiple fronts, the ability to efficiently bring projects across the finish line has never been more critical. We heard this sentiment from many industry professionals and end users during the event.

We’re seeing a considerable softening in the supply chain industry coupled with a manpower shortage for execution, affecting integrators and manufacturers. As we move forward, companies’ success will increasingly hinge on their execution capabilities.

Execution isn’t just about getting the job done; it’s about meeting the industry’s evolving demands with a turnkey, efficient approach.

Companies with a reliable workforce, well-established processes, and a strong reputation for forecasting deliverables accurately are setting themselves apart. These companies will not only survive but thrive in this changing landscape.

On the integrator side, the key to success lies in collaborating closely with clients, crafting engineered solutions that are not only custom but also uniquely tailored to each customer’s specific needs. The real value comes from delivering these solutions on time without compromising quality or professionalism.

“Project excellence is no longer just an aspiration; it’s a fundamental requirement for staying relevant and competitive in the supply chain industry,” says Schumacher. “Companies that prioritize precise execution and can adapt to rapid changes will lead the way.”

#3 More Versatile, Long-Lasting Partnerships

The ongoing supply chain labor shortage prompts businesses to seek partners capable of delivering more comprehensive services. Partner value propositions must increase to offer broader solutions that reduce client complexity.

The essence of partnership versatility is not only delivering an array of products but also providing end-to-end services. Clients are now prioritizing vendors who can handle multiple aspects of a project, from installation and setup to providing additional turnkey solutions.

This shift adds value and streamlines processes, minimizing the number of touchpoints for the end user. Partnerships that cultivate this versatility in their products and services can more effectively adapt to the client’s unique challenges.

“The significance of automation, project execution, and versatile partnerships cannot be overstated as the industry navigates this period of labor shortages and rapid industry evolution,” concludes Schumacher. “These are not just isolated trends but vital components of a resilient supply chain strategy.”

Steele Solutions is at the forefront of addressing these challenges. With our expertise in engineering and design, project management, and on-site field management, we can help your supply chain business adapt and thrive. Contact us today and discover how we can help you turn your response to these industry trends into competitive advantages.